Web Menu

Product Search

Exit Menu

A Comprehensive Guide to Cylindrical Cell Modul

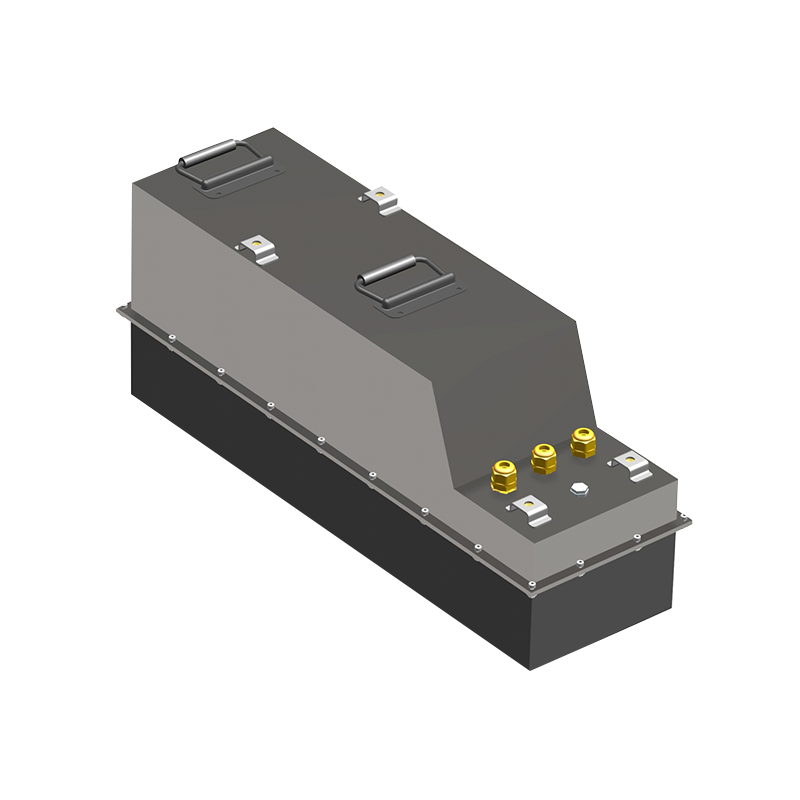

China Cylindrical Prismatic Cell Module Manufacturing Exporter

Cylindrical cell modules have been a significant component in the field of energy storage and power systems. They are widely recognized for their versatility and reliability, making them a popular choice for various applications.

Cylindrical cell modules are characterized by their cylindrical shape, which is a departure from the more common flat, rectangular cell designs. The cylindrical form factor offers several advantages, including better heat dissipation and structural integrity. The cells are typically composed of a metal casing that houses the electrochemical components, including the anode, cathode, and electrolyte. The cylindrical design allows for a more efficient use of space within the casing, pilot higher energy density compared to other shapes.

The operation of cylindrical cell modules is based on the principles of electrochemistry. During discharge, lithium ions move from the anode to the cathode through the electrolyte, generating an electric current. Conversely, during charging, the ions move back to the anode, storing energy for later use. The cylindrical shape facilitates this ion movement, as it allows for a more direct path and less resistance compared to other cell configurations.

Cylindrical cell modules are used in a wide range of applications due to their robustness and adaptability. They are commonly found in consumer electronics, such as laptops and power tools, where high energy density and reliability are crucial. In the automotive industry, cylindrical cells are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs), providing the necessary power for propulsion and auxiliary systems. Additionally, they are employed in large-scale energy storage systems, where their ability to withstand high discharge rates and long cycle life is particularly beneficial.

One of the key advantages of cylindrical cell modules is their ability to handle high currents without significant degradation. This makes them ideal for applications that require rapid charging and discharging, such as in power tools and electric vehicles. The cylindrical shape also allows for better heat management, which is crucial for maintaining the longevity and safety of the cells.

However, there are challenges associated with cylindrical cell modules. The manufacturing process can be more complex and costly compared to other cell types, due to the need for precise metal casings and the intricacies of the internal structure. Additionally, the cylindrical shape can limit the design flexibility of devices that incorporate these cells, as the cells must be accommodated within the device's form factor.

As technology advances, the manufacturing of cylindrical cell modules is expected to evolve. Improvements in materials science, such as the development of new electrolytes and cathode materials, could pilot higher energy densities and faster charging times. Automation in the manufacturing process may also reduce costs and increase efficiency, making cylindrical cells more competitive in the market.

In conclusion, cylindrical cell modules play a vital role in the energy storage landscape. Their unique design and functionality make them suitable for a variety of applications, from small consumer electronics to large-scale industrial use. As research and development continue, the performance and affordability of cylindrical cell modules are likely to improve, further expanding their reach and impact on modern technology.

-

+86-13049701086

-

Stonehuang@CGONEN.com

-

No.88, Huji Road, Taizhou Bay Binhai New Area, Jiaojiang District, Taizhou City, Zhejiang Province, China